What Is the Purpose of PP Partition in FMCG?

In the FMCG (Fast-Moving Consumer Goods) industry, the main purpose of PP (Polypropylene) partition packaging is to protect, separate, and organize products during storage, transportation, and distribution.

FMCG products move in high volumes and at high speed, so even small damages can cause major losses. PP partitions ensure that products do not touch, collide, leak, or deform while moving through the supply chain. Click Here To Product Detail.

Key Purposes:

-

Prevent breakage and leakage

-

Maintain product shape and appearance

-

Improve packing speed and organization

-

Support bulk and repeat transportation

-

Reduce product rejection and returns

Why PP Partition Is Used in FMCG Industry

The FMCG industry deals with products that are:

-

Fragile (bottles, jars)

-

Liquid-filled (shampoos, oils, beverages)

-

Shape-sensitive (cosmetics, food containers)

-

High-volume and fast-moving

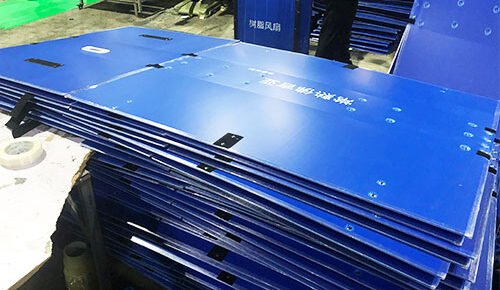

PP partitions are preferred because they are lightweight, reusable, moisture-resistant, and cost-effective over time, making them ideal for repetitive FMCG logistics. Click Here To View Product.

Step-by-Step: How PP Partition Works in FMCG Packaging

Step 1: Product Identification

First, the FMCG product type is identified—such as bottles, jars, pouches, or containers.

Step 2: Product Measurement

Exact product dimensions (height, diameter, width) are measured to design accurate partition cells.

Step 3: Partition Design Selection

Based on product type:

-

Tight-fit cells for bottles and jars

-

Standard grid for containers

-

Reinforced edges for heavier FMCG items Click Here To View Product.

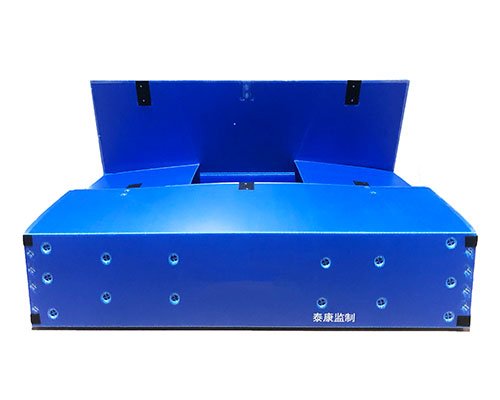

Step 4: Placement Inside Box or Crate

The PP partition is placed inside a carton, plastic crate, or reusable box, dividing it into equal compartments.

Step 5: Product Loading

Each FMCG product is placed into an individual cell, preventing direct contact with other items.

Step 6: Sealing & Transportation

Once filled, the box is sealed and moved through storage, transport, and distribution safely.

How to Install PP Partition in FMCG Packaging (Step-by-Step)

Installing PP partitions is simple and does not require tools.

Installation Steps:

-

Open the carton or crate fully

-

Insert the pre-slotted PP partition

-

Interlock vertical and horizontal sheets

-

Ensure the partition fits tightly inside the box

-

Check that cells are uniform and stable

-

Place products gently into each compartment

-

Close and seal the box

✔ No glue or fasteners required

✔ Easy to remove and reuse Click Here To View Product.

Advantages of PP Partition Packaging in FMCG

Protection & Quality

-

Prevents bottle breakage and leakage

-

Avoids scratches and deformation

-

Maintains shelf-ready appearance

Operational Efficiency

-

Faster packing and unpacking

-

Easy product identification

-

Better warehouse organization

Cost & Sustainability

-

Reusable for multiple cycles

-

Reduces packaging replacement cost

-

Recyclable and eco-friendly

Performance

-

Moisture-resistant (ideal for liquids)

-

Chemical-resistant (for detergents, cleaners)

-

Lightweight, reducing transport cost Click Here To View Product.

Disadvantages of PP Partition in FMCG

-

Higher initial cost than cardboard dividers

-

Not biodegradable (though recyclable)

-

Can deform under extreme heat

-

Not suitable for very heavy items unless thick grade is used

-

Requires customization for best performance

These disadvantages are usually outweighed by long-term savings and reduced damage. Click Here To View Product.

FMCG Products Best Suited for PP Partition Packaging

PP partitions are commonly used for:

-

Shampoo and conditioner bottles

-

Cooking oil bottles

-

Beverage bottles and jars

-

Cosmetic containers and creams

-

Detergent and cleaning product bottles

-

Glass food jars and sauces

-

Personal care product packaging

Best Practices for Using PP Partitions in FMCG

-

Use tight-fit cells for liquid bottles

-

Choose 3–5 mm thickness for most FMCG items

-

Clean partitions regularly for hygiene

-

Use color-coded partitions for SKU identification

-

Combine with returnable crates for cost savings

-

Inspect partitions after multiple reuse cycles Click Here To View Product.

Summary: Why PP Partition Matters in FMCG

PP Partition packaging plays a critical role in the FMCG industry by protecting products, improving efficiency, and reducing waste. It supports high-speed logistics, minimizes damage, and helps brands maintain product quality from factory to retail shelf.

Though the initial cost is higher than disposable packaging, its reusability, durability, and performance make PP partition a smart and sustainable solution for FMCG operations.