What Is the Purpose of PP Bubble Guard Boxes and Bins in Logistics and Warehousing?

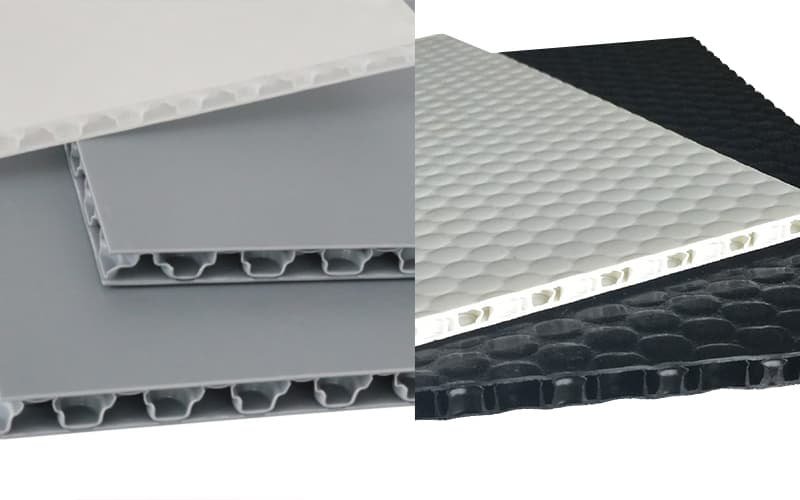

In Logistics and Warehousing, the main purpose of PP Bubble Guard Boxes and Bins is to protect goods from impact, vibration, stacking pressure, and surface damage during storage, handling, and transportation.

Warehouses and logistics operations involve frequent movement, stacking, loading, unloading, and long-distance transport. PP Bubble Guard boxes and bins provide built-in cushioning, ensuring products remain safe and damage-free throughout the supply chain. Click Here To Product Details.

Key Purposes:

-

Absorb shock and vibration during handling

-

Prevent scratches, dents, and breakage

-

Protect products during stacking and palletization

-

Reduce transit and handling damage

-

Improve storage safety and efficiency

Why PP Bubble Guard Boxes and Bins Are Used in Logistics and Warehousing

Logistics and warehousing operations handle:

-

Mixed product categories

-

High-volume and bulk shipments

-

Frequent loading and unloading

-

Returnable packaging systems

-

Long storage durations

PP Bubble Guard boxes and bins are preferred because they are lightweight, reusable, durable, moisture-resistant, and cost-effective for repeated logistics cycles. Click Here To View Product.

Step-by-Step: How PP Bubble Guard Boxes and Bins Work in Logistics Packaging

Step 1: Product Classification

Products such as electronics, auto parts, FMCG goods, pharma items, or fragile components are identified.

Step 2: Box or Bin Selection

Correct size, load capacity, and bubble thickness are selected based on product weight and fragility.

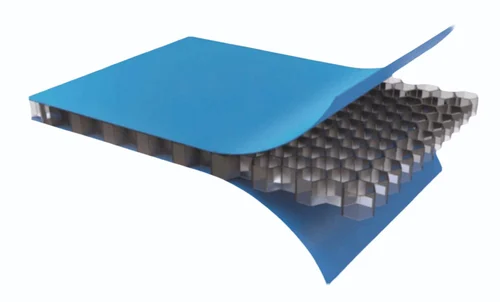

Step 3: Bubble Guard Cushioning Setup

-

Bubble Guard used as internal lining

-

Extra layers added for fragile or high-value goods

-

Dividers or separators added if required

Step 4: Product Loading

Products are placed inside the bubble-protected box or bin to avoid movement and contact.

Step 5: Stacking and Storage

Boxes and bins are stacked safely in racks or pallets without damaging the contents.

Step 6: Transportation & Distribution

Packages are transported safely across warehouses, distribution centers, and end customers. Click Here To View Product.

How to Use and Install PP Bubble Guard Boxes and Bins (Step-by-Step)

PP Bubble Guard boxes and bins are designed for quick setup and easy reuse.

Installation Steps:

-

Open or assemble the box/bin

-

Line all internal sides with PP Bubble Guard sheets

-

Secure the liner to prevent shifting

-

Place products carefully inside

-

Add top cushioning if required

-

Close, seal, and label the package

✔ No adhesive required

✔ Easy to clean and reuse

✔ Ideal for returnable logistics systems Click Here To View Product.

Advantages of PP Bubble Guard Boxes and Bins in Logistics and Warehousing

Protection & Safety

-

Excellent shock and vibration absorption

-

Prevents transit and handling damage

-

Maintains product surface quality

Operational Efficiency

-

Faster packing and unpacking

-

Organized storage and easy handling

-

Reduces product loss and claims

Cost & Sustainability

-

Reusable for multiple transport cycles

-

Reduces packaging replacement costs

-

Fully recyclable and eco-friendly

Performance Benefits

-

Moisture and dust resistant

-

Lightweight yet strong

-

Long service life compared to disposable packaging Click Here To View Product.

Disadvantages of PP Bubble Guard Boxes and Bins in Logistics Packaging

-

Higher initial investment than cardboard boxes

-

Not biodegradable (but recyclable)

-

Extreme heat may cause deformation

-

Requires proper storage to maintain shape

However, for high-volume and returnable logistics, the long-term benefits outweigh the drawbacks. Click Here To View Product.

Products Best Suited for PP Bubble Guard Boxes and Bins in Logistics

These boxes and bins are ideal for:

-

Electronic components and devices

-

Automotive spare parts

-

FMCG and cosmetic products

-

Pharmaceutical items

-

Glass and fragile goods

-

Industrial tools and assemblies

Best Practices for Using PP Bubble Guard Boxes and Bins in Warehousing

-

Select correct bubble size based on product weight

-

Avoid overloading bins

-

Use stackable designs for space optimization

-

Clean liners regularly for reuse

-

Inspect for damage after each logistics cycle

-

Combine with pallets for safer transport Click Here To View Product.

Summary: Why PP Bubble Guard Boxes and Bins Matter in Logistics and Warehousing

PP Bubble Guard Boxes and Bins play a crucial role in logistics and warehousing by providing reliable cushioning, product protection, and reusable packaging solutions. They help reduce damage, improve storage efficiency, and support sustainable supply chain operations.

While the upfront cost is higher than disposable packaging, the durability, reusability, and reduced product loss make PP Bubble Guard boxes and bins a smart investment for modern logistics and warehousing systems.