What Is the Purpose of PP Bubble Guard Boxes and Bins in the Electronics Industry?

In the Electronics Industry, the primary purpose of PP Bubble Guard Boxes and Bins is to protect sensitive electronic components from shock, vibration, surface damage, moisture, and electrostatic discharge (ESD) during storage, transportation, and handling.

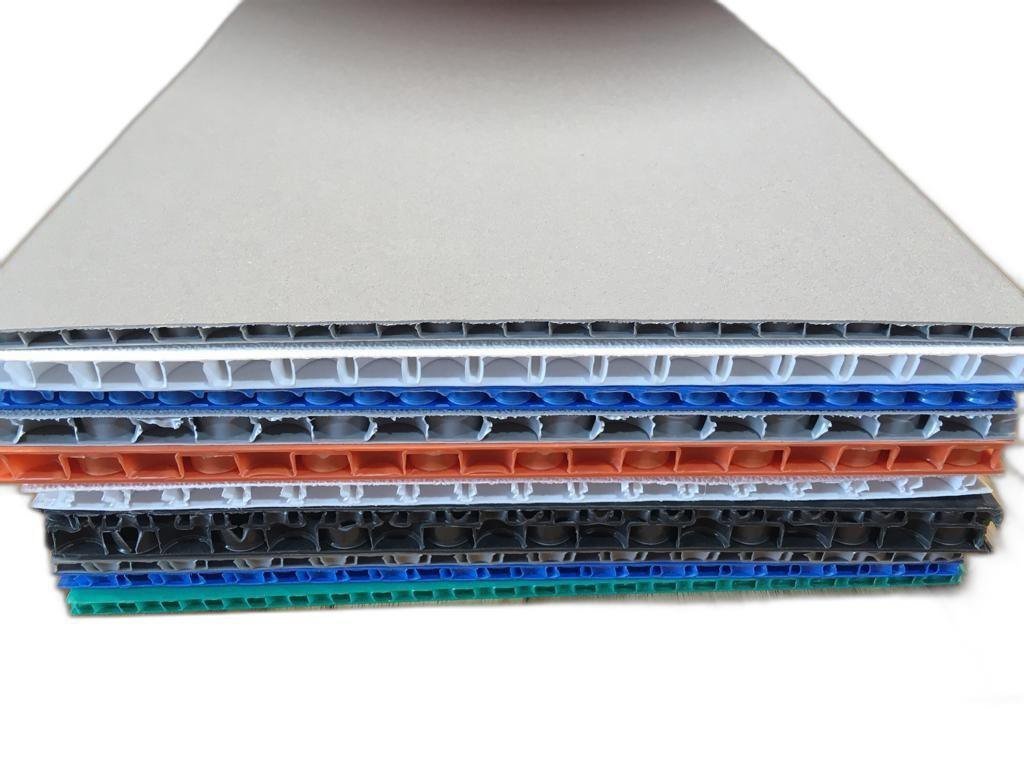

Electronic components are highly delicate and vulnerable to physical impact and static electricity. PP Bubble Guard boxes and bins provide built-in cushioning and protective separation, ensuring safe movement throughout the electronics supply chain. Click Here To Product Details.

Key Purposes:

-

Absorb shock and vibration during transport

-

Prevent scratches, cracks, and surface damage

-

Reduce electrostatic (ESD) risk

-

Protect high-value and precision components

-

Minimize product rejection and returns

Why PP Bubble Guard Boxes and Bins Are Used in the Electronics Industry

The electronics industry handles products that are:

-

Fragile and precision-engineered

-

Highly sensitive to static electricity

-

Lightweight but high-value

-

Transported in bulk and frequently reused

-

Require clean and organized packaging systems

PP Bubble Guard boxes and bins are preferred because they are lightweight, reusable, moisture-resistant, and available in anti-static (ESD-safe) grades, making them ideal for electronics packaging. Click Here To View Product.

Step-by-Step: How PP Bubble Guard Boxes and Bins Work in Electronics Packaging

Step 1: Product Identification

Electronic products such as PCBs, ICs, connectors, sensors, chips, modules, or display components are identified.

Step 2: Product Measurement

Exact dimensions and weight are measured to select the correct box or bin size and bubble thickness.

Step 3: Bubble Guard Design Selection

-

Fine bubbles for lightweight, delicate components

-

Medium or large bubbles for heavier electronic modules

-

ESD-safe Bubble Guard for static-sensitive items

Step 4: Placement Inside Box or Bin

PP Bubble Guard sheets are used as liners or cushioning inside PP corrugated boxes, plastic bins, or ESD-safe containers.

Step 5: Product Loading

Each electronic component is placed carefully inside the bubble-protected box or bin to prevent movement and contact.

Step 6: Sealing & Transportation

The box or bin is sealed and transported safely to manufacturing plants, warehouses, or customers.Click Here To View Product.

How to Use and Install PP Bubble Guard Boxes and Bins in Electronics Packaging

PP Bubble Guard boxes and bins are designed for easy installation and reuse, suitable for cleanroom and controlled environments.

Installation Steps:

-

Open or assemble the box or bin

-

Line the inner surfaces with PP Bubble Guard sheets

-

Secure the liner to prevent shifting

-

Place electronic products carefully

-

Add extra layers for high-value or fragile items

-

Close and seal the container

✔ No glue required

✔ Easy to remove, clean, and reuse Click Here To View Product.

Advantages of PP Bubble Guard Boxes and Bins in the Electronics Industry

Protection & Cushioning

-

Excellent shock and vibration absorption

-

Prevents scratches and surface damage

-

Protects fragile electronic components

Safety & Performance

-

Available in anti-static (ESD-safe) material

-

Moisture resistant

-

Lightweight yet durable

Operational Efficiency

-

Organized and secure component storage

-

Faster packing and unpacking

-

Reduced handling errors

Cost & Sustainability

-

Reusable for multiple cycles

-

Reduces long-term packaging costs

-

Fully recyclable and eco-friendly Click Here To View Product.

Disadvantages of PP Bubble Guard Boxes and Bins in Electronics Packaging

-

Higher initial cost compared to standard bubble wrap

-

Not biodegradable (but recyclable)

-

Requires ESD-grade material for sensitive components

-

Can deform under extreme heat

-

Custom designs may increase upfront cost

Despite these limitations, PP Bubble Guard boxes and bins provide superior protection and long-term value.

Electronics Products Best Suited for PP Bubble Guard Boxes and Bins

PP Bubble Guard boxes and bins are commonly used for:

-

Printed Circuit Boards (PCBs)

-

Integrated Circuits (ICs)

-

Sensors and connectors

-

Mobile phone components

-

LED panels and displays

-

Electronic modules and accessories Click Here To View Product.

Best Practices for Using PP Bubble Guard Boxes and Bins in the Electronics Industry

-

Use ESD-safe Bubble Guard for static-sensitive items

-

Select correct bubble size and thickness

-

Avoid product movement inside the bin

-

Clean bubble guard liners regularly

-

Inspect for wear after repeated use

-

Use returnable containers for cost efficiency

Summary: Why PP Bubble Guard Boxes and Bins Matter in the Electronics Industry

PP Bubble Guard Boxes and Bins play a critical role in the electronics industry by offering advanced cushioning, ESD protection, and reusable packaging solutions. They help protect sensitive components, improve handling efficiency, and reduce damage throughout the supply chain. Although the initial investment is higher than disposable materials, the long service life, reduced product loss, and operational efficiency make PP Bubble Guard boxes and bins a smart and sustainable packaging solution for electronics manufacturers and suppliers.