Role of Plastic Pallets in the Engineering Industry

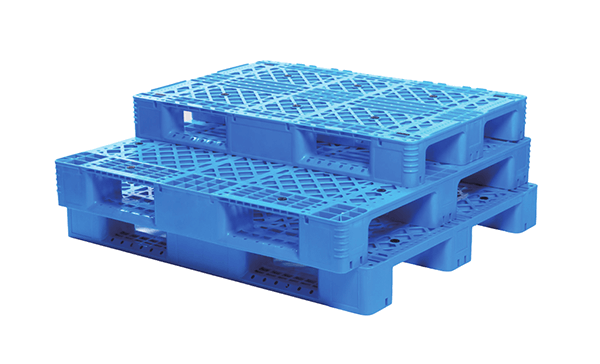

Plastic pallets provide a dependable, clean, and dimensionally consistent foundation for handling, storing, and transporting engineered components, assemblies, and heavy machinery parts. Their high impact resistance, precise tolerances, and resistance to moisture and chemicals make them ideal for engineering environments where cleanliness, repeatable handling, and protection from contamination are important. Available in rackable, nestable, and heavy-duty formats — including reinforced and skid-style designs — plastic pallets reduce product damage, support automation, and deliver long service life with low maintenance. Click Here To View Product Detail.

Key Applications of Plastic Pallets in the Engineering Industry

Heavy-Load Support & Consistent Strength

Plastic pallets engineered for heavy duty loads distribute weight evenly and resist deformation, making them suitable for gearboxes, motor housings, castings, and machined assemblies. Their molded construction provides consistent load-bearing characteristics across the fleet.

Protection from Corrosion & Chemical Exposure

Non-absorbent plastics resist oils, coolants, solvents, and other chemicals commonly found in workshops and factories. This protects components and prevents pallet deterioration that can lead to contamination or part staining.

Precision Handling for Automation & Material-Handling Systems

Tight dimensional tolerances ensure smooth integration with conveyors, automated palletizers, forklifts, and AS/RS — minimizing jams, misalignments, and downtime in high-throughput production lines.

Load Stability & Securement Options

Anti-slip deck patterns, perimeter lips, integrated tie-down points, and compatible skids help secure crates, bins, and strapped assemblies. When combined with edge protectors or stretch film, pallets reduce load shift and impact damage during transport.

Cleanability & Reduced Contamination Risk

Plastic pallets do not splinter, retain metal shavings, or absorb liquids—helping maintain cleaner storage and production areas. They’re easy to wash or pressure-clean, which lowers particulate and lubricant transfer to sensitive parts.

Traceability & Asset Management

Plastic pallets accept molded serials, RFID tags, or barcode plates for tracking returned tools, work-in-progress kits, and serialized assemblies — improving traceability across manufacturing and service workflows.

Space & Return Logistics Efficiency

Nestable and stackable options reduce storage footprint and lower return freight costs for empty pallets, improving logistics economics for circulating pallet pools and multi-site operations. Click Here To View Product.

Significance of Plastic Pallet Packaging in Engineering Workflows

Plastic pallets are critical in engineering because they combine mechanical robustness, chemical resistance, and dimensional precision. Their predictable performance reduces the risk of dropped loads and handling damage to expensive components, while their cleanable surfaces limit contamination in assembly and finishing areas. The long lifecycle and low maintenance requirements of plastic pallets lower total cost of ownership compared with frequently replaced wooden alternatives. For production lines that rely on automation and repeatable handling, plastic pallets deliver reliability that supports throughput, traceability, and product quality. KRC Packaging supplies heavy-duty, rackable, and ESD-capable plastic pallets tailored for engineering environments. Click Here To View Product.

Best Practices When Using Plastic Pallets in Engineering

• Select pallets rated for the maximum static and dynamic loads you expect, including racking loads.

• Use anti-slip overlays, strap points, or edge restraints for irregular-shaped or stacked items.

• Clean pallets regularly to remove metal fines, oils, and cutting fluids that could contaminate parts.

• Implement RFID or barcode tagging for WIP tracking and returnable asset management.

• Match pallet footprint to conveyors, racks, and handling equipment to prevent misfeeds and handling errors. Click Here To View Product.

Conclusion: Improving Engineering Logistics with Plastic Pallet Solutions

In summary, plastic pallets offer a robust, low-maintenance, and contamination-resistant platform that protects engineered components throughout manufacturing, storage, and transport. Their strength, automation compatibility, and cleanability make them a strategic choice for OEMs, contract manufacturers, and MRO providers focused on quality, uptime, and lifecycle value. KRC Packaging delivers engineered plastic pallet solutions designed to meet rigorous load, handling, and cleanliness demands of modern engineering operations.