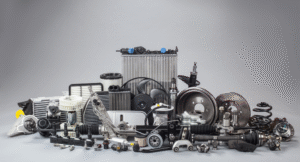

How PP Partition Packaging Drives Efficiency and Protection in the Automotive Industry

In the fast-paced and precision-driven automotive industry, packaging solutions play a vital role in ensuring the safe handling, transport, and storage of critical components. One such solution gaining widespread popularity is the PP (Polypropylene) Partition. These partitions are specially designed inserts made from durable polypropylene sheets, customized to fit within boxes or crates and segment them into smaller compartments. Here’s how they serve the automotive sector effectively: Click Here To Product details.

- Protects Components During Transit

- Efficient Storage and Handling

- Reusable and Cost-Effective

- Chemical and Oil Resistance

- Customizable for Complex Shapes

- Lightweight and Eco-Conscious

How PP Partition Enhances Automotive Industry Packaging

In the automotive industry, PP (Polypropylene) Partitions are extensively used to enhance packaging efficiency, protect valuable components, and support lean manufacturing systems. Here’s how they are typically used:

1.In-Transit Protection of Auto Parts

Automotive parts, whether small fasteners or large molded components like bumpers and panels, are susceptible to damage during shipping. PP partitions hold each part securely in place, preventing scratches, dents, or breakage. This ensures that every item reaches its destination in factory-perfect condition.

2.Assembly Line Organization

Assembly lines demand organized workflows. PP partitions allow for neat arrangement of parts such as clips, bolts, sensors, and wiring components. Workers can quickly identify and retrieve needed items, improving efficiency and reducing errors.

3.Returnable Packaging Systems

Unlike single-use packaging, PP partitions are strong, washable, and built for repeated use. They form an essential part of returnable packaging systems used between suppliers and manufacturers. Over time, they reduce the cost and environmental impact associated with disposable packaging materials. Click Here To View Product.

4.Customized Fit for Complex Auto Components

Automotive parts often have contact with oils, greases, or other industrial fluids. PP partitions are chemically resistant, making them ideal for storing and transporting lubricated or greasy components without degradation or contamination.

5.Storage of Oily or Greasy Components

From side mirrors to instrument panels, automotive parts come in all shapes and sizes. PP partitions can be precisely die-cut or thermo-formed to snugly fit around these components, eliminating unnecessary movement and minimizing packaging volume.

6.Lightweight and Eco-Conscious

Polypropylene is not only light, helping reduce the overall shipping weight, but also recyclable. By using PP partitions, automotive companies move toward more sustainable practices while also reducing fuel costs in transportation.

In summary, PP partitions offer a smart and sustainable solution for packaging in the automotive industry. Their ability to protect, organize, and adapt makes them indispensable on the shop floor and in transit logistics.

Why PP Partition Packaging Matters in the Automotive Industry

In the automotive industry, where precision, safety, and efficiency are paramount, PP (Polypropylene) Partition packaging plays a crucial role. It provides a reliable way to protect sensitive auto components such as electronic modules, painted parts, and fragile assemblies during handling, storage, and transportation. These partitions prevent damage caused by movement or collision, reducing the chances of costly rework or replacement. Moreover, PP partitions support organized storage, enabling smooth workflow on assembly lines and quicker access to parts. Their durability and reusability make them a preferred choice in returnable packaging systems, helping reduce packaging waste and operational costs. Resistant to chemicals and oils, PP partitions are ideal for housing greasy or lubricated components without risk of contamination. Overall, PP partition packaging contributes significantly to quality control, cost savings, and sustainability in the automotive supply chain. Click Here To View Product.

Final Thoughts on PP Partition in the Automotive Industry

PP Partition packaging has become an essential component in the automotive industry, offering a smart, protective, and cost-effective solution for handling a wide range of vehicle parts. Its ability to prevent damage, improve organization, and support reusable packaging systems makes it a practical choice for manufacturers and suppliers alike. As the industry moves toward greater efficiency and sustainability, PP partitions continue to play a vital role in streamlining logistics, reducing waste, and maintaining product integrity throughout the supply chain.