What Is the Purpose of PP Partition in the Electronics Industry?

In the Electronics Industry, the main purpose of PP (Polypropylene) partition packaging is to protect sensitive electronic components, separate individual parts, and maintain organized handling during storage, transportation, and production flow. Click Here To Product Detail.

Electronic products are highly sensitive to impact, vibration, and static electricity. PP partitions prevent components from touching, colliding, or shifting, ensuring safe movement throughout the supply chain.

Key Purposes:

-

Prevent physical damage and component breakage

-

Protect against scratches and surface damage

-

Minimize vibration and movement during transit

-

Support safe handling of sensitive electronics

-

Reduce product rejection and failure rates Click Here To View Product.

Why PP Partition Is Used in the Electronics Industry

The electronics industry handles products that are:

-

Fragile (PCBs, chips, sensors)

-

Static-sensitive (ICs, control units)

-

Precision-made and high-value

-

Small to medium-sized with complex shapes

-

Produced and transported in high volumes

PP partitions are preferred because they are lightweight, durable, customizable, and available in anti-static (ESD-safe) variants, making them ideal for electronics packaging. Click Here To View Product.

Step-by-Step: How PP Partition Works in Electronics Packaging

Step 1: Component Identification

First, the electronic component type is identified—such as PCBs, ICs, sensors, connectors, or control modules.

Step 2: Component Measurement

Exact dimensions (length, width, height, thickness) are measured to design precise partition cells.

Step 3: Partition Design Selection

Based on component type:

-

Tight-fit cells for PCBs and ICs

-

Standard grid for connectors and modules

-

Reinforced cells for heavier electronic assemblies Click Here To View Product.

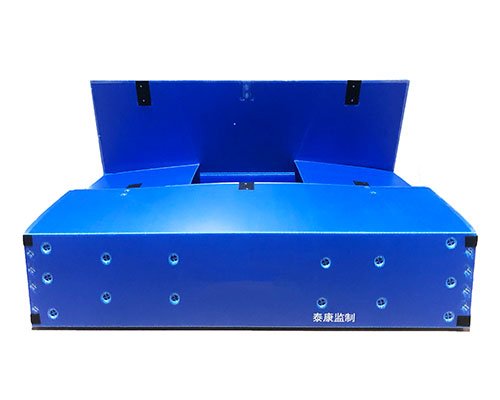

Step 4: Placement Inside Box or Crate

The PP partition is placed inside an ESD-safe carton, plastic crate, or returnable box, dividing it into secure compartments.

Step 5: Component Loading

Each electronic part is placed into an individual cell, avoiding contact with other components.

Step 6: Sealing & Transportation

The box is sealed and moved through storage, internal handling, or transportation safely.

How to Install PP Partition in Electronics Packaging (Step-by-Step)

PP partitions are easy to install and require no special tools. Click Here To View Product.

Installation Steps:

-

Open the ESD-safe carton or crate

-

Insert the pre-slotted PP partition

-

Interlock vertical and horizontal sheets

-

Ensure the partition fits tightly inside

-

Check that cells are uniform and stable

-

Place electronic components carefully

-

Close and seal the container

✔ No glue or fasteners required

✔ Easy to remove and reuse

Advantages of PP Partition Packaging in the Electronics Industry

Protection & Safety

-

Prevents impact and vibration damage

-

Protects delicate surfaces and connectors

-

Available in anti-static / ESD-safe material

Operational Efficiency

-

Faster packing and unpacking

-

Easy identification of components

-

Improved assembly line workflow

Cost & Sustainability

-

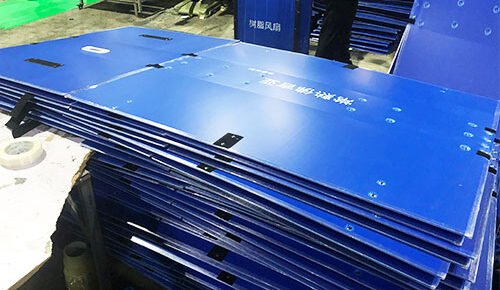

Reusable for multiple cycles

-

Reduces packaging replacement costs

-

Recyclable and environmentally friendly Click Here To View Product.

Performance

-

Lightweight yet strong

-

Moisture and dust resistant

-

Maintains structural integrity over repeated use

Disadvantages of PP Partition in Electronics Packaging

-

Higher initial cost compared to cardboard dividers

-

Not biodegradable (though recyclable)

-

Requires ESD-safe material for static-sensitive parts

-

Can deform under extreme heat

-

Customization needed for complex components

Despite these limitations, long-term reliability and protection make PP partitions the preferred choice. Click Here To View Product.

Electronic Products Best Suited for PP Partition Packaging

PP partitions are commonly used for:

-

Printed Circuit Boards (PCBs)

-

Integrated Circuits (ICs)

-

Sensors and control units

-

Connectors and wiring components

-

Consumer electronics modules

-

Precision electronic assemblies

Best Practices for Using PP Partitions in the Electronics Industry

-

Use ESD-safe PP partitions for static-sensitive parts

-

Choose tight-fit cells for PCBs and chips

-

Select proper PP thickness based on component weight

-

Clean partitions regularly to prevent dust buildup

-

Use color-coded partitions for component identification

-

Inspect partitions after repeated use Click Here To View Product.

Summary: Why PP Partition Matters in the Electronics Industry

PP Partition packaging plays a vital role in the electronics industry by protecting sensitive components, improving handling efficiency, and reducing damage-related losses. Its anti-static capability, durability, and reusability make it an ideal packaging solution for modern electronics manufacturing and logistics.

Though the initial investment is higher than disposable packaging, the long-term cost savings, improved product safety, and sustainability benefits make PP partitions a smart choice for electronics operations.