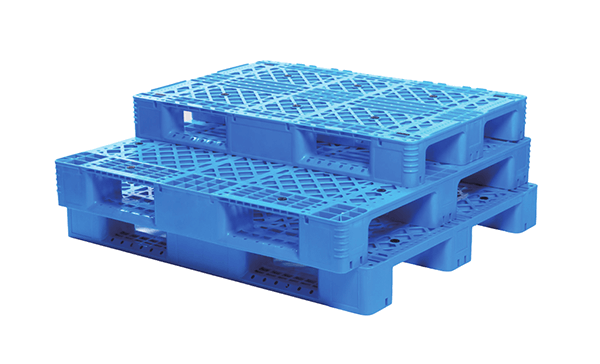

Essential Role of Plastic Pallets in Automotive Packaging and Logistics

Plastic pallets play a crucial role in the automotive industry by ensuring safe, durable, and efficient handling of vehicle components and spare parts. Unlike traditional wooden pallets, plastic pallets are resistant to moisture, chemicals, and pests, making them ideal for transporting sensitive automotive parts such as engines, bumpers, gearboxes, and electronic modules. Their uniform design supports load stability during transportation and storage, reducing the risk of shifting or damage. Additionally, plastic pallets are lightweight yet strong, enabling cost-effective logistics while maintaining the quality and safety of automotive components. Their reusability and hygiene standards make them a sustainable choice for modern automotive supply chains. Click Here To View Product Detail.

Key Applications of Plastic Pallets in the Automotive Industry

Heavy-Duty Component Handling

Plastic pallets are widely used to transport heavy automotive components like engines, transmissions, and suspension systems. Their high load-bearing capacity ensures safe handling without pallet breakage.

Safe Transport of Large Auto Parts

Parts such as bumpers, dashboards, and doors can be securely stacked on plastic pallets. Their smooth, non-porous surface prevents scratches and surface damage during handling.

Protection Against Contamination

Plastic pallets resist moisture, oil, and chemicals often present in automotive plants and warehouses. This keeps sensitive parts, especially electronic modules, free from corrosion or contamination.

Enhanced Warehouse & Logistics Efficiency

Standardized plastic pallets allow seamless stacking, racking, and forklift handling. Their consistent size improves warehouse space utilization and streamlines supply chain operations.

Sustainable & Reusable Solution

Unlike wooden pallets, plastic pallets are reusable and have a longer lifespan. Their durability reduces replacement costs while supporting sustainability goals in automotive logistics. Click Here To View Product.

Significance of Plastic Pallets in the Automotive Sector

Plastic pallets are essential in the automotive industry for safe, hygienic, and efficient transportation of critical parts. They eliminate issues like splintering, nail hazards, and contamination commonly associated with wood pallets. Their durability ensures load stability for heavy and irregularly shaped components, reducing risks during storage and transit. With their uniform design, plastic pallets improve stacking efficiency and streamline supply chain operations. Their reusability also supports cost savings and sustainability, making them the preferred choice for automotive manufacturers and suppliers.

KRC Packaging offers high-quality plastic pallet solutions tailored to meet the heavy-duty demands of the automotive sector.Click Here To View Product.

Conclusion: Strengthening Automotive Supply Chains with Plastic Pallets

Plastic pallets provide a reliable, durable, and sustainable solution for automotive packaging and logistics. From securing heavy components to preventing contamination, they ensure safe handling across the supply chain. Their reusability reduces costs, while their standardized design enhances warehouse efficiency and transport safety. Overall, plastic pallets are a long-term investment that improves productivity, safety, and sustainability in the automotive industry.

KRC Packaging delivers strong, reusable, and customized plastic pallet solutions designed to meet the diverse needs of the automotive industry.