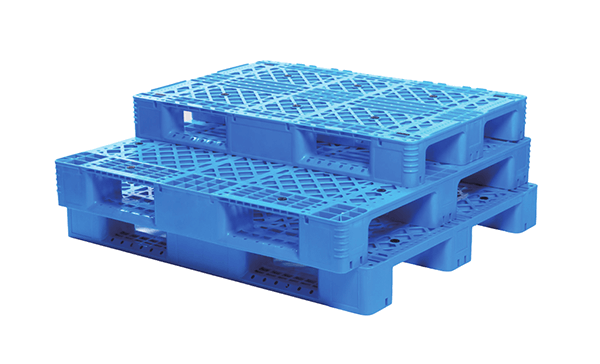

Understanding Plastic Pallets and Their Role in Secure Packaging

Plastic pallets are durable, reusable platforms engineered from high-quality polymers (often HDPE or PP) to store and transport goods safely. Unlike wood, they are non-porous, splinter-free, and resistant to moisture and chemicals—reducing contamination risks and improving hygiene. Their consistent dimensions enhance compatibility with conveyors, AS/RS, and robotic handling, while options like rackable, nestable, and export-grade designs fit varied supply-chain needs. With long service life and low maintenance, plastic pallets provide a cost-effective, clean, and reliable packaging base that boosts load integrity. Their smooth, debris-free surfaces also support stringent quality standards and FOD control in sensitive industries. Click Here To More Product.

Key Benefits and Applications of Plastic Pallet Packaging

Load Stability & Safety

Plastic pallets deliver uniform deck strength and optional anti-slip features to keep unit loads stable in transit and storage.

Protection from Moisture & Chemicals

Non-absorbent construction resists water, oils, and many chemicals—protecting packaging and products from degradation.

Improved Handling Efficiency

Precision molding ensures consistent dimensions for smooth forklift, pallet jack, and automated system handling, reducing product and pallet damage.

Hygiene & Contamination Control

Easy to clean and sanitize; no nails, splinters, or wood dust. Ideal where cleanliness and FOD control are critical.

Cost-Effective Over Lifecycle

High durability, repair-free construction, and reduced product damage deliver attractive total cost of ownership.

Versatile & Trackable

Available in nestable/rackable designs with perimeter lips, runners, and RFID/barcode options for inventory visibility and fast audits. Click Here To View Product.

Major Industries Dependent on Plastic Pallet Packaging Solutions

Agriculture Industry

Plastic pallets withstand washdowns and outdoor conditions, keeping produce and inputs clean and dry. Nestable designs cut back-haul costs and yard space.

Automotive Industry

Uniform deck strength and rackable options support heavy parts, totes, and kitted assemblies. Clean, splinter-free handling reduces component rework.

Electronics Industry

Non-porous, low-debris surfaces and optional ESD-safe variants help protect sensitive electronics and enable cleanroom-adjacent workflows.

Food & Beverage Industry

Sanitizable, HACCP-friendly pallets support hygiene standards across processing, cold chain, and retail distribution.

Engineering & Industrial Fabrication

High load capacities and tie-down compatibility secure irregular or heavy items; consistent footprints streamline warehouse flows.

Aeronautical Industry

FOD-minimizing, moisture-resistant pallets safeguard high-value aircraft components and integrate well with automation and export logistics. Click Here To View Product.

Why Plastic Pallet Packaging is Essential for Modern Industries

Plastic pallets enhance product safety, hygiene, and handling efficiency throughout the supply chain. Their dimensional consistency supports automation, while durability reduces breakage, downtime, and load failures. Resistance to moisture and chemicals preserves packaging integrity and reduces waste. With options for tracking technology and space-saving nestable designs, they streamline inventory control and logistics—lowering total system costs and improving sustainability through long service life and recyclability.

KRC Packaging provides high-quality plastic pallet solutions tailored to diverse industrial needs—including rackable, nestable, hygienic, and export models—ensuring product safety and supply-chain efficiency. Click Here To View Product.

Comprehensive Advantages of Plastic Pallet Packaging and KRC’s Industry Solutions

Plastic pallets deliver a clean, consistent, and long-lasting foundation for secure packaging across agriculture, electronics, food, automotive, engineering, and aeronautics. Their ability to resist contaminants, stabilize loads, and work seamlessly with modern handling systems makes them a cornerstone of efficient logistics. By reducing damage, improving hygiene, and enabling better inventory visibility, plastic pallets help businesses cut costs and elevate operational performance—end to end.

- Plastic Pallets in the Aeronautical Industry: Durable, Hygienic, and Efficient Packaging Solutions

- Benefits and Uses of Plastic Pallets in the Agriculture Industry | KRC Packaging Solutions

- Plastic Pallets in the Food & Beverage Industry: Hygiene, Safety & Efficiency | KRC Packaging

- Plastic Pallets in the Engineering Industry: Strength, Safety & Efficiency | KRC Packaging

- Plastic Pallets in the Automotive Industry: Durable, Safe & Efficient Logistics | KRC Packaging

- Plastic Pallets in Electronics Industry: Benefits, Applications & Smart Solutions by KRC Packaging